Quality

Highest standards as a benchmark

We divide our production process using the Upcast method into the following main steps:

Production of the main tube by UpCast, reduction of the tube diameter to the desired level with drawing and forming machines and annealing of the final product with bright annealing furnaces.

1

Melting and casting:

In this process, tube production is initiated by moulding through UpCast furnaces. First, cathode grade A is melted together with phosphor bronze in a 9-tonne induction furnace, and after obtaining the desired alloy, the melt is transferred to a 7-tonne holding furnace. High pouring is then used to directly form the main tubes in sizes 38/33 and 52/47 (OD / ID) and transfer them into special baskets.

2

Primary drawing:

The diameter and thickness of the primary pipes produced in the previous section are only two 120, depending on the design of the production process.

kN is reduced by the ASMAG drawing machine.

3

Medium annealing:

As the drawing process is carried out at cold temper, the drawn tubes are passed through an annealing furnace to relieve these stresses. This furnace is also an Austrian ASMAG product.

4

Secondary drawing: (Spinner Block)

The drawn tubes from the old section are transferred to two spinner block machines, one in the final size. The difference between this machine and the main drawing machine is the drawing times, which allow us to produce diameters from 4 to 30 millimetres. These machines are also manufactured by the Austrian ASMAG.

5

Level Winder

After sizing, the tubes to be sold are sent to levelling coils. In this section, the tube passes through the eddy current device and faulty parts of the tube are marked with this device or neglected if necessary. The number of defects is checked according to the standards. The tubes are wound in coils of 100-150 kg. All the machinery equipment is Austrian ASMAG.

6

Finishing:

In the final section, the pipes are cut flat or creped depending on the customer’s order. This machine can cut webs up to 6 metres and pancakes from 15 to 50 metres. This machine is from the Austrian ASMAG.

7

Final annealing:

In this unit, the coil and wafer tubes are heated to a suitable temperature in the final annealing furnace to restore their physical properties such as workability, electrical properties, cold forming as well as a shiny surface. They are then kept at the same temperature for a while and finally cooled at a rate suitable for the ambient temperature. To prevent oxidation of the tubes, oxygen is extracted instead and nitrogen is pumped into the furnace.

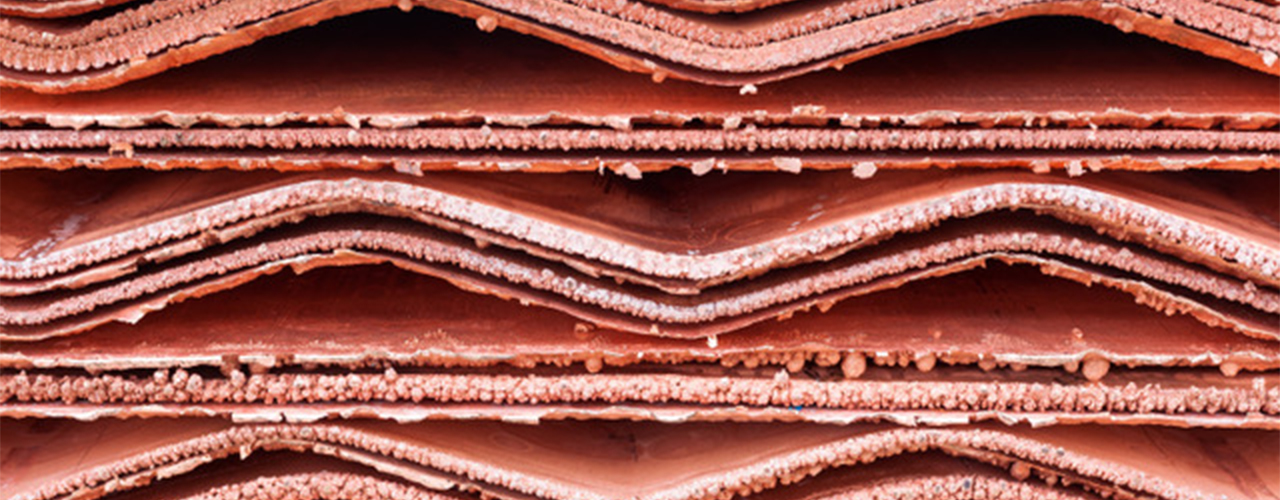

Copper Cathode

Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Contact us for further information.

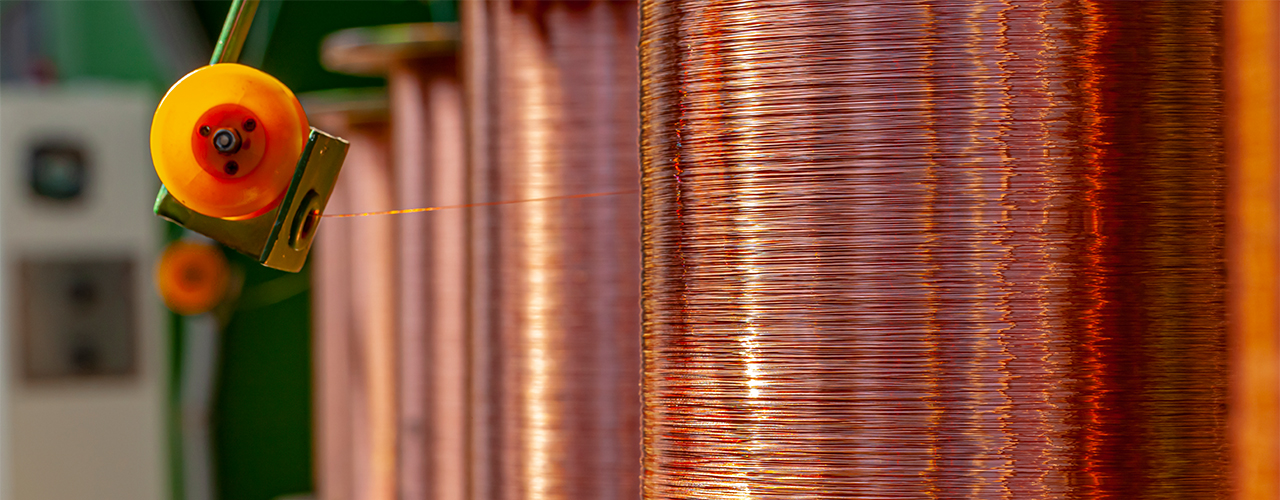

Copper Wire Scrap

Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Contact us for further information.

Copper Ore

Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Contact us for further information.

Copper Concentrate

Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Contact us for further information.

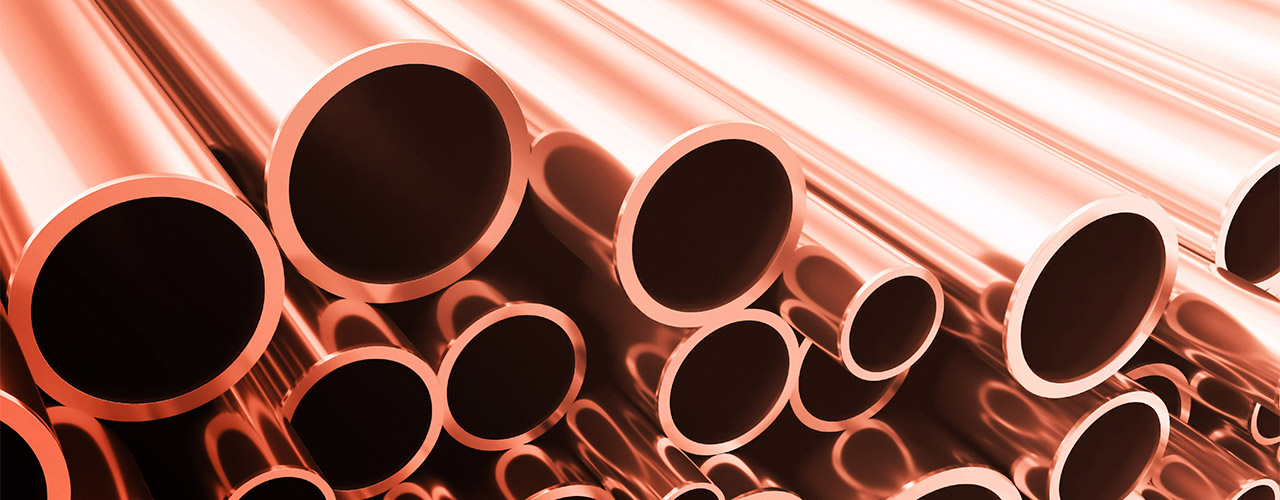

Copper Tubes

Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Contact us for further information.

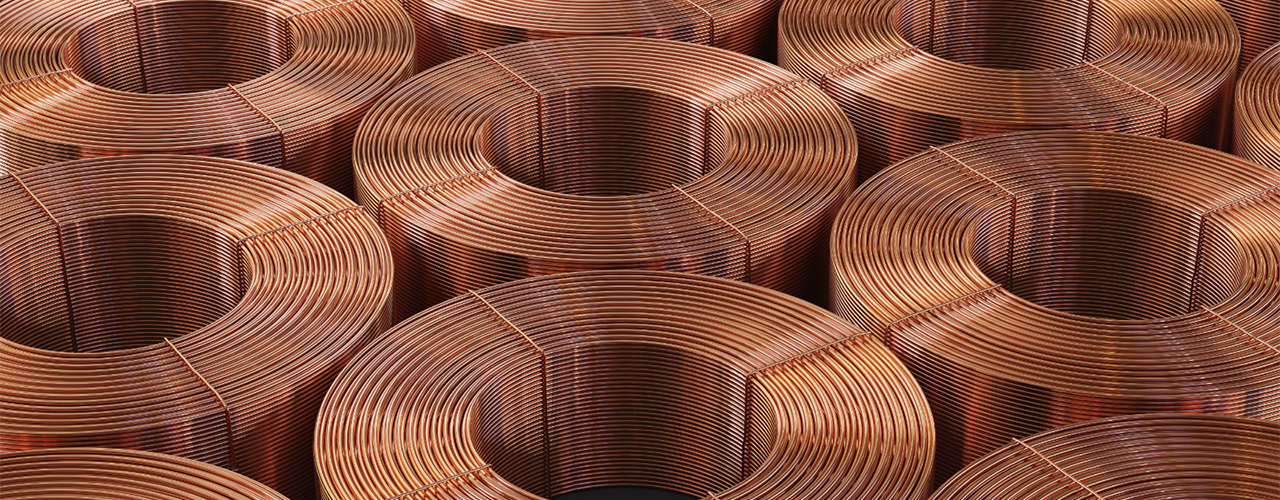

Copper Tube Coils

Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Contact us for further information.

Do not hesitate to contact us.

Do you have any questions about our services or our products? Write us an e-mail. We look forward to hearing from you.